Tank Cleaning for New Lubricant Refill

Customer Challenge

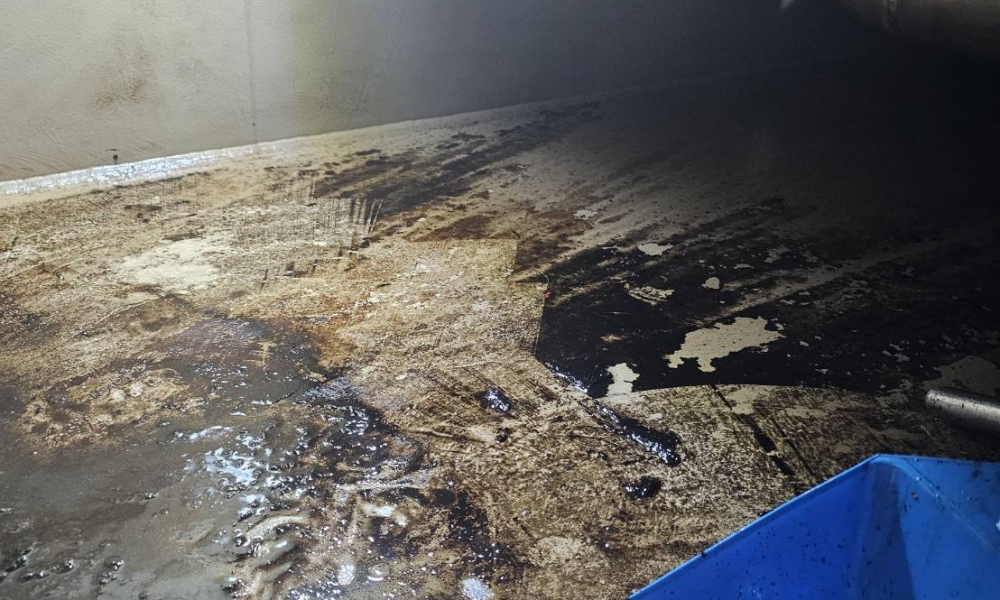

A customer required a complete tank cleaning before filling it with a new batch of lubricant. The existing tank had accumulated significant contamination, sludge, and varnish residues, which posed the following risks:

- Contamination of New Lubricant – Leftover sludge and varnish could reduce lubricant performance.

- Equipment Reliability Issues – Unclean tanks could introduce contaminants into the system, leading to potential failures.

- Operational Downtime – The cleaning process needed to be efficient to minimize downtime.

To ensure optimal lubricant performance and maintain system reliability, the customer sought Lubefix’s professional cleaning service.

Lubefix Solution

Lubefix deployed a certified confined space team to clean the system thoroughly. The process involved the following steps:

✅ Pre-Cleaning Safety Procedures:

- Conducted gas level measurements to ensure a safe working environment before entering the tank.

- Verified that the team members held certified confined space entry permits to comply with safety regulations.

✅ Tank Cleaning Execution:

- Used specialized cleaning tools to remove varnish, sludge, and contaminants.

- Ensured complete removal of deposits to prevent contamination of the new lubricant.

- Conducted a final inspection to confirm that the tank was free of residual contamination.

Results & Impact

| Parameter | Before Cleaning | After Cleaning |

|---|---|---|

| Tank Condition | Heavy sludge and varnish buildup | Fully cleaned and contamination-free |

| Lubricant Contamination Risk | High | Eliminated |

| Operational Safety | Unsafe due to gas accumulation | Gas levels measured and controlled |

🔹 Ensured Clean Oil Fill-Up – Eliminated contamination risks for the new lubricant.

🔹 Enhanced System Reliability – Reduced potential wear and failures caused by sludge.

🔹 Compliant with Safety Standards – Used proper confined space procedures for worker safety.

Before & After Images

|

Before

|

After |

|

|

Customer Feedback

The customer was highly satisfied with Lubefix’s tank cleaning service, noting that the process was efficient, professional, and safety-compliant. The clean tank ensured that the new lubricant would perform at optimal levels without contamination concerns.

Conclusion

Lubefix successfully cleaned the tank, eliminating contamination and ensuring a safe and clean refill. This case highlights the importance of professional tank cleaning before lubricant changes to maintain optimal system performance and reliability.