Achieving Low Moisture and Particulate Control with Vacuum Dehydration

Customer Challenge

A customer required a comprehensive de-watering and particulate filtration solution to achieve an low moisture target of <0.02% in their lubrication system.

Challenges and Risks:

🔹 High Water Contamination – Excess moisture in the lubricant could lead to oil oxidation, corrosion, and reduced lubricant performance.

🔹 Particulate Contamination – Solid contaminants could increase wear and damage to bearings, pumps, and valves.

🔹 Lubricant Degradation – High water content could reduce oil viscosity and fire resistance properties, leading to increased maintenance costs and operational risks.

To maintain optimal machine performance, the customer required a solution that could efficiently remove both water and particulate contamination while ensuring continuous operation.

Lubefix Solution

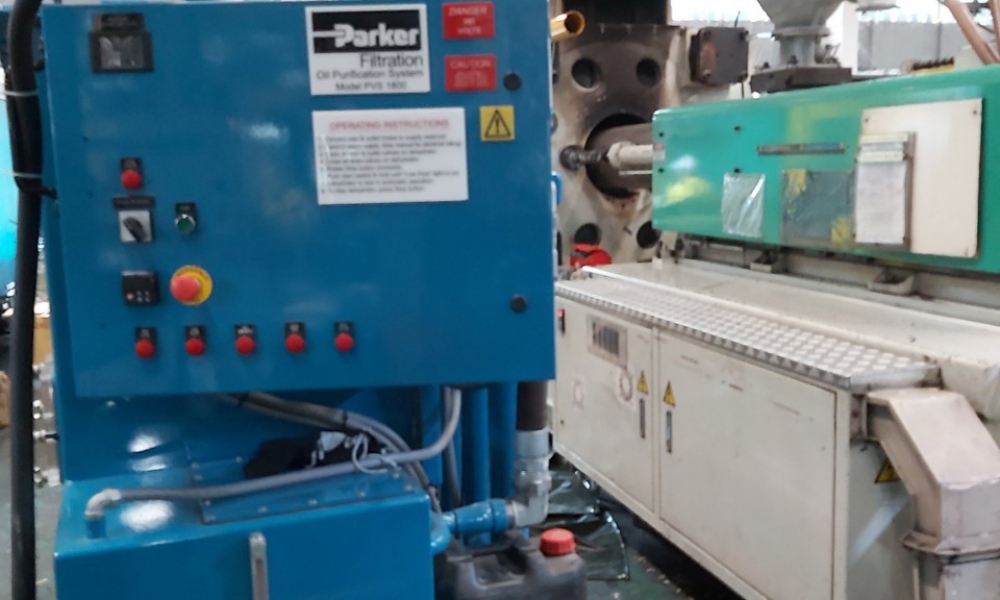

To meet the customer's strict moisture and cleanliness requirements, Lubefix installed a Vacuum Dehydration Unit (VDU) to efficiently remove water and contaminants from the lubrication system.

Step-by-Step Implementation:

1️⃣ Installation of Vacuum Dehydration Unit (VDU)

- Utilized vacuum dehydration technology to remove dissolved, emulsified, and free water.

- Applied low-temperature, high-vacuum distillation to evaporate moisture without degrading the lubricant.

2️⃣ Particulate Filtration for Enhanced Cleanliness

- Integrated high-efficiency filtration elements to remove fine particulate contaminants.

- Ensured that solid particles were continuously filtered to prevent system wear and damage.

3️⃣ Continuous Moisture Monitoring & System Optimization

- Implemented real-time monitoring to track moisture reduction progress.

- Adjusted system parameters to achieve the target moisture level of <0.02%.

Results & Impact

| Parameter | Before Lubefix Solution | After Lubefix Solution |

|---|---|---|

| Moisture Content | Above 0.02% | Reduced to <0.02% |

| Particulate Contamination | High | Significantly reduced |

| Lubricant Condition | Prone to oxidation and degradation | Restored and stabilized |

| Operational Risk | High risk of corrosion and component failure | Extended equipment life and reliability |

✅ Achieved target moisture level of <0.02% using Vacuum Dehydration Technology

✅ Enhanced lubricant performance and extended service life

✅ Prevented corrosion, oxidation, and system failures

✅ Reduced maintenance downtime and operational costs

Customer Feedback

The customer was highly satisfied with Lubefix’s Vacuum Dehydration solution, as it effectively controlled moisture and particulate contamination while keeping the lubricant system in peak operational condition.

Conclusion

By implementing Lubefix’s advanced Vacuum Dehydration Unit, the customer successfully achieved a moisture level of <0.02%, ensuring optimal lubrication performance, extended equipment lifespan, and reduced maintenance costs.