CASE STUDIES

-

Power Plant (Operator)

Bangkok

Power Plant (Operator)

Bangkok

Scheduled turnaround services Contamination measurement and High Velocity Oil Flushing(HVOF). -

Power Plant (Construction)

Rayong

Power Plant (Construction)

Rayong

Plant Commissioning project Contamination measurement Oil fill and Drain Out Manage Flushing Oil Oil Analysis -

Power Plant (Operator)

Rayong

Power Plant (Operator)

Rayong

Scheduled turnaround services Contamination measurement Varnish Mitigation Oil Fill and Drain Out Tank Cleaning High Velocity Oil Flushing (HVOF) -

Power Plant (Operator)

Rayong

Power Plant (Operator)

Rayong

De-Watering Control Oil Achieve 200 ppm -

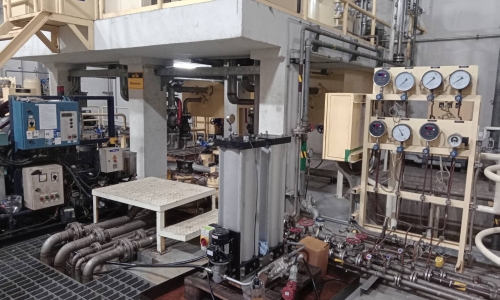

Steel Plant

Chonburi

Steel Plant

Chonburi

Scheduled turnaround services Reservoir Cleaning Oil Fill and Drain Out -

Copper Plant

Chonburi

Copper Plant

Chonburi

Oil Fill and Drain Out Cleaning Oil Tank Oil Filtration Target NAS 1638 Class 7 -

Steel Plant

Rayong

Steel Plant

Rayong

Scheduled Oil Change services Oil Fill and Drain Out -

Steel Plant

Rayong

Steel Plant

Rayong

Scheduled Oil Change services Oil Fill and Drain Out -

General Manufacturers

Rayong

General Manufacturers

Rayong

Oil Fill and Drain Out Cleaning Oil Tank Oil Filtration Target NAS 1638 Class 7 -

通过真空脱水技术实现超低湿度和颗粒污染控制

通过真空脱水技术实现超低湿度和颗粒污染控制

客户需要 全面的除水和颗粒过滤解决方案,以实现润滑系统中 超低湿度目标 (<0.02%)。 -

在不停产情况下去除润滑油油槽中的水污染

Chonburi

在不停产情况下去除润滑油油槽中的水污染

Chonburi

某制造工厂的 换热器 发生泄漏,导致润滑油油槽严重受水污染。经过检测,水含量高达 55,000 ppm (5.5%) -

实现 NAS 1638 7 级清洁度的换油和加油过程

实现 NAS 1638 7 级清洁度的换油和加油过程

客户需要 完整的润滑油排放和加注流程,并确保新润滑油达到 NAS 1638 7 级清洁度标准。 -

案例研究:降低泰国某水电站的高油漆污染水平

案例研究:降低泰国某水电站的高油漆污染水平

泰国某大型水电站的涡轮润滑系统遭遇了严重的油漆污染。客户报告称,膜片颜色比色法(MPC) 值已达到 55 的危急水平 -

新润滑油填充前的油罐清洗

新润滑油填充前的油罐清洗

某客户需要在填充新批次润滑油之前,对储油罐进行彻底清洗。现有油罐长期使用后,已积累了大量 污染物、油泥和油漆残留物, -

通过湿度控制解决耐火液污染问题

通过湿度控制解决耐火液污染问题

一家制造工厂在长期使用 耐火液(Fire-Resistant Fluid) 后,出现了严重的污染问题。 -

在换油和系统冲洗过程中实现 NAS 6 级清洁度

在换油和系统冲洗过程中实现 NAS 6 级清洁度

客户需要对 机器设备进行换油和系统冲洗,以确保设备能够在最佳状态下运行。